Synthetic fuels to the rescue?

Fossil fuels could be replaced by less polluting synthetic fuel alternatives. Renewable diesel and bio-diesel can replace petroleum diesel. E-methanol, bio-methanol or solar methanol can replace methanol and green hydrogen can replace blue and grey hydrogen. However, these more sustainable fuels are expensive, most have limited availability and have numerous other challenges.

Fossil fuels have 80% share in the global energy supply

To decarbonize, these fossil fuels could be replaced by less polluting alternatives

Renewable diesel and bio-diesel can replace petroleum diesel…

…e-methanol, bio-methanol or solar methanol can replace methanol and…

…green hydrogen can replace blue and grey hydrogen

But these more sustainable fuels are expensive, most have limited availability and have numerous other challenges

Introduction

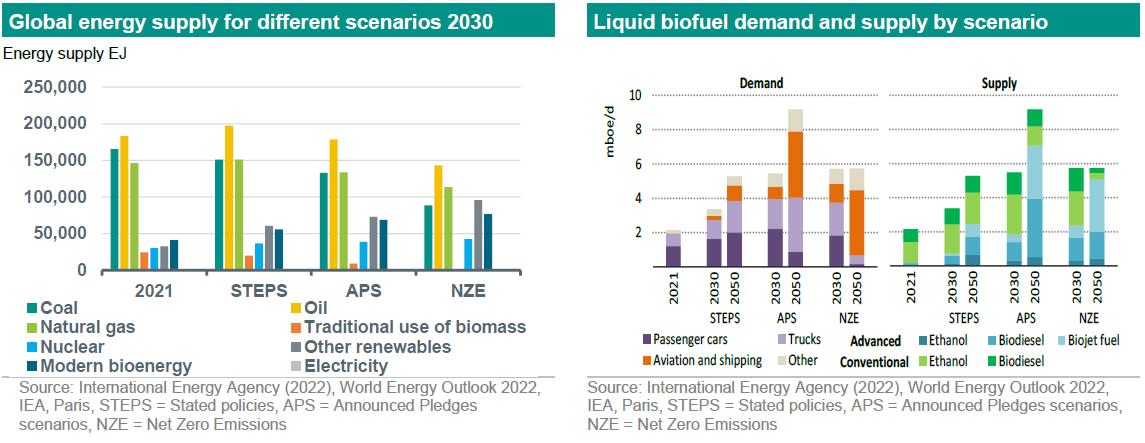

Fossil fuels play a crucial role in our economy. According to the IEA global energy supply for coal, natural gas and oil took a share of close to 80% in 2021 (see graph below). To reach net-zero by 2050, we need to reduce our dependency on burning fossil fuels. Renewables and bio-energy will play a crucial role. The main problem with renewables is intermittency, so they come and go and patterns can be difficult to predict. We focussed on renewables and how to tackle the intermittency challenge in earlier publications on solar, wind, heating and battery technologies. In this report we focus on fuels that can replace fossil fuels but that emit less or no CO2. The graph on the left below shows the share of modern bio-energy in 2021 (6.6%) and the role the IEA expects it to play in the different scenarios in 2030.

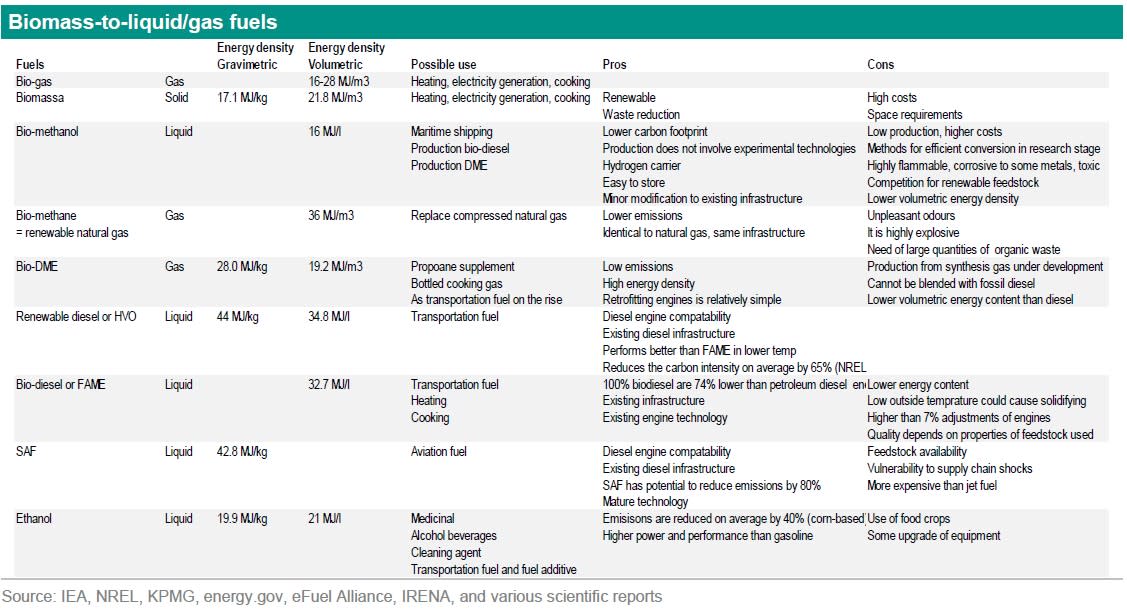

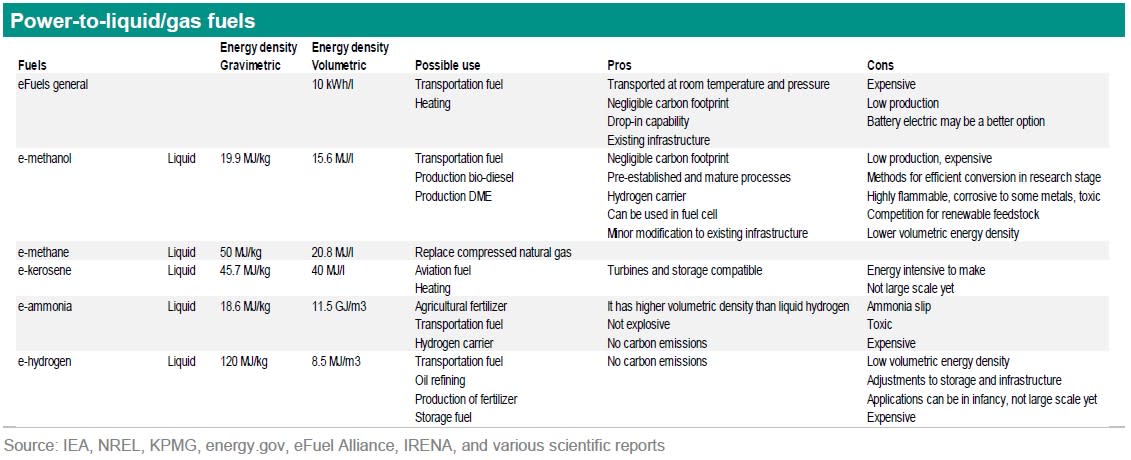

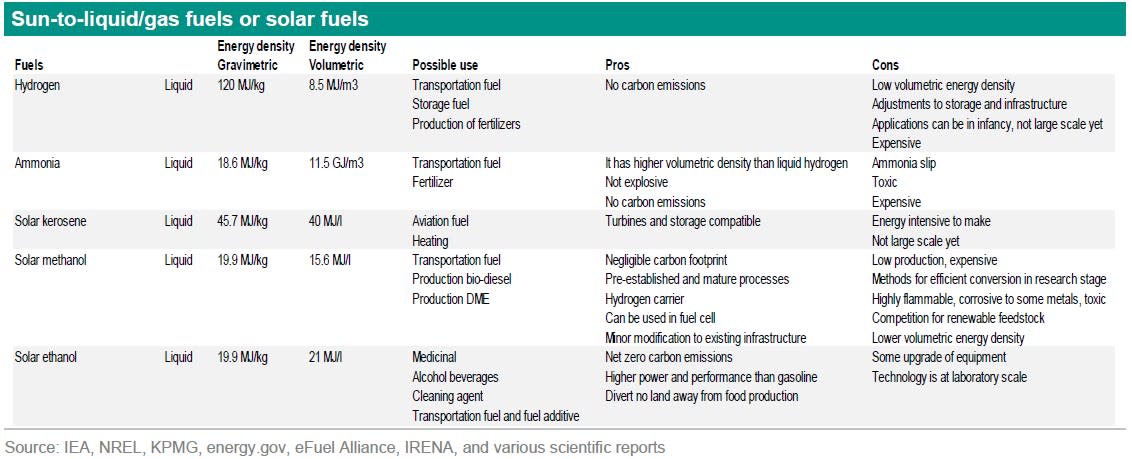

Replacing fossil fuels by more sustainable fuels

Replacing fossil fuels by fuels that emit less or no emissions seem easy. But in reality it is a complicated endeavour. For a start there are many different types of more sustainable fuels (more on this below). Every fuels has its own characteristics and therefore different fuels would be suitable for different applications. Fuels can for example be compared on the basis of their emission intensity, their energy density, storage needs, safety, costs and fuel infrastructure and production. Different fuels have different energy density levels, which can be measured in terms of equivalent energy released through combustion. Energy density can be measured in gravimetric energy density (per unit of mass) or volumetric energy density (per unit of volume). Gravimetric energy density is relevant when comparing the energy efficiency of fuels. At the same time, volumetric energy density is relevant when comparing transportation modes as storage space (fuel tank) must be present to carry the fuel propelling a vehicle. The higher the energy density, the higher the fuel quality, which is inversely proportional to its chemical complexity. In the tables later in the text we compare different fuels by type.

Moreover, to replace fossil fuels by more sustainable equivalents, changes need to be made to for example engines or the infrastructure and storage. Furthermore, the supply, production and price of more sustainable fuels are less favourable compared to fossil fuels and this will take time to change. The production of synthetic fuels need large amounts of green electricity and feedstock and there is often competition for these sources. In some cases the technology is not commercially available yet. So production needs to increase and prices needs to come down. Despite this more sustainable fuels will have a larger role to play to achieve a net zero economy globally by 2050.These fuels are also called synthetic fuels.

What are synthetic fuels?

Synthetic fuels are liquid fuels that have the same properties as fossil fuels but are produced artificially. Synthetic fuels can be blended with fossil fuels or replace the fossil fuel in internal combustion engines. These synthetic fuels are used for different purposes and different sectors. There are three types of synthetic fuels and the way they are produced makes them distinctive (source ).

Biomass-to-liquid/gas produces biofuels (any fuel that is derived from biomass) such as renewable diesel/hydrotreated vegetable oil (HVO) and Sustainable Aviation Fuel (SAF)

Power-to-liquid/gas produces e-fuels (electro fuels) such as e-methane, e-kerosine, e-methanol and hydrogen.

Bio-fuels and bio-mass

Bio-fuels can be produced by agricultural waste, food waste, manure and sewage. There are liquid and solid bio-fuels. Examples of liquid bio-fuels are bio-gas, bio-methane, bio-LPG. Charcoal, biochar and biofuel pellets are examples of solid bio-fuels. The bio-fuel production is categorized into four generations based on the type of feedstock used. First generation bio-fuels primarily utilize crops that are high in sugar, starch, or oil content. Second generation bio-fuels are derived from lignocellulosic biomass. This can be from agricultural residue, waste or dedicated biomass plants. Third generation bio-fuels are produced from microalgae such as bio-diesel and seaweed, mainly for bio-ethanol. Fourth generation bio-fuels are generated from genetically modified microalgae. The graphs above on the right show demand and supply of liquid biofuels in 2030 and 2050 in different scenarios.

Burning sustainably-resourced wood is carbon neutral as the CO2 emissions emitted during burning are equal to trapped emissions during the growth of the trees. Bio-gas is produced by the breakdown of organic matter. It is a mixture of methane, hydrogen and carbon dioxide. The methane content of biogas typically ranges from 45-74% by volume, with most of the remainder being CO2 (). The precise composition of bio-gas depends on the type of feedstock and the production pathways. Bio-methane is a bio-gas from which the carbon dioxide, hydrogen sulfide and water have been removed. It Is also known as renewable natural gas. As a result of the purification process, the bio-methane has the same characteristics as natural gas. So bio-methane is the purified form of raw bio-gas. The combustion of these creates CO2 emissions, but since the bio-gas is derived from plants (which remove CO2 from the atmosphere ) the CO2 emissions are generally considered carbon neutral.

Bio-methanol is produced by fermenting biomass such as wood or agricultural waste using microorganisms that are cable of producing methanol. Bio-methanol is simply methanol produced from biomass and other non-fossil sources. Methanol, the alcohol with the simplest chemical structure (CH3OH), is a colourless, tasteless liquid with a faint odour. Methanol (including bio and e-methanol) is seen as a promising alternative fuel for maritime shipping. Dimethyl ether or DME is produced from methanol by simple dehydration. It is a gas that can be liquified at moderate pressure. DME is a diesel fuel substitute but it can also replace LPG in applications such as heating and cooking.

Bio-LPG is produced from renewable sources including biological oil and fats and the fermentation of glucose by microorganism. It has a lower carbon footprint than conventional LPG (up to 80% lower). It is identical in its chemical structure to conventional LPG. It can be used as drop-in fuel and in existing gas boilers.

Bio-diesel is a renewable fuel that can be manufactured from vegetable oils, animal fats or recycled cooking grease for use in diesel vehicles. It can be produced through four different methods: oil-blends, micro-emulsion, pyrolysis and transesterification. Transesterification is an eco-friendly chemical process in which the fatty acids react with the alcohol to produce biodiesel and glycerol. Renewable diesel is a fuel made from fats and oils and is processed to be chemically the same as petroleum diesel. It can be used as a replacement fuel or blended with any amount of petroleum diesel. The production process is different than with biodiesel but it is coming from similar feedstock. It has a better resilience to bacterial growth in comparison to biodiesel. Therefore a better solution for longer and standby applications. It has a lower density and energy content than diesel. Renewable diesel meets the conventional specification allowing it to be used in existing infrastructure and diesel engines. Hydrogenated Vegetable Oil (HVO) is made from a variety of vegetable oils and fats containing triglycerides and fatty acids. Another name is hydro-processes esters and fatty acids (HEFA). It is also called renewable diesel. Sustainable aviation fuel or SAF is made from non-petroleum feedstocks. It can be blended at different levels with limits from 10%-50%, depending on the feedstock and how the fuel is produced. Ethanol is a renewable fuel made from corn and other plant materials. It is used in various applications such as cleaning agents and transportation fuel.

Power to liquid fuels

Next to bio-fuels and bio-mass also power-to-liquid fuels could be used to replace fossil fuels. These are synthetically produced liquid hydrocarbon. Renewable energy is the key energy source, and water and carbon dioxide are the main resources. First renewable electricity is generated, which then drives an electrolyser that splits water into hydrogen and oxygen. Next, the hydrogen is mixed with carbon dioxide and turned into syngas via the reverse water gas shift (RWGS) reaction – a process that is conducted at high temperatures and driven by electricity. The mobility sector will likely use a lot of these fuels in the future for the hard to abate sectors. E-methanol is methanol produced using renewable electricity.

Sun-to-liquid fuels or solar fuels

Solar fuels are synthetic chemical fuels produced from solar energy. Solar fuels are fuels made from common substances like water and carbon dioxide using the energy of sunlight. Options for solar fuels include making hydrogen as a fuel by using solar energy to split water, or producing alcohols such as ethanol and methanol by using solar energy to reduce carbon dioxide with hydrogen, or creating less-conventional fuels such as ammonia by using solar energy to reduce nitrogen with hydrogen (source: ).

Fuel additive and improved fuel

Next to replacing a fossil fuel by a more sustainable fuel, the fossil fuel can also be improved to reduce energy use and hence emissions. This can be done by adding fuel additives. Fuel additives are chemicals that can be added to gasoline to improve vehicle performance or help maintain systems. However, some additives could damage the electronics or the engine. There is also an improved fuel. For example Change XL. Change XL add enzymes to a conventional fuel. These enzymes break down long and complex molecular chains in the fuels and saturate the fuel mixture with oxygen. They break down the (condensed) water present in fuel and prevents problems with bacteria, moulds and yeasts by eliminating and dissolving them in the fuel. This results in a more stable, homogeneous fuel. The enzymes continue to work actively throughout the fuel chain. Change XL claims to reduce emissions by 10% and fuel savings of up to 10%. This improved fuel can be used in the existing infrastructure.

Emissions

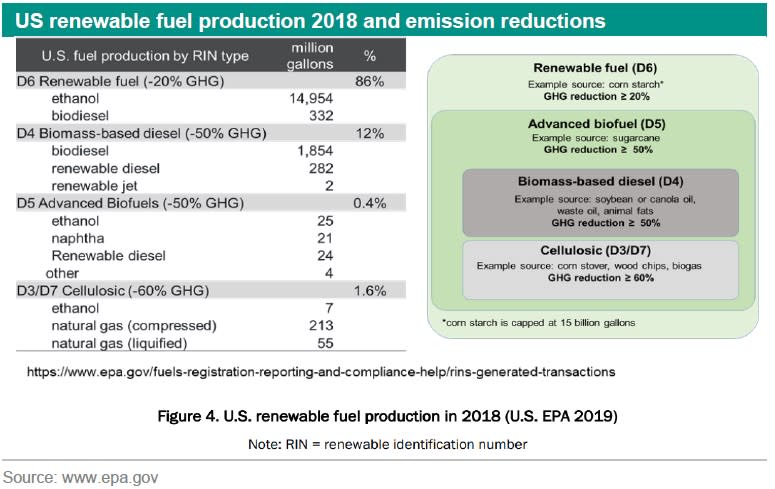

Are synthetic fuels low carbon, carbon-neutral or zero-carbon fuels? Low carbon fuels emit less carbon than fossil fuels. Renewable diesel, bio-diesel, hydrogen/methanol/ammonia when produced using fossil fuels with carbon capture and storage are examples of low carbon fuels. Renewable diesel’s CO2 emissions are highly dependent on the feedstock used. Often, this results in life-cycle emissions above zero. The higher the blend-in percentage, the higher the CO2 reduction. The National Renewable Energy Laboratory (NREL) indicates that renewable diesel reduces the carbon intensity level on average by 65%. According to the NREL pure bio diesel (100%) reduces carbon dioxide emissions by more than 75% compared to petroleum diesel. The graph above shows emissions reductions of renewable fuel produced in the US.

Carbon neutral fuels are fuels that do not increase or decrease the amount of carbon in the atmosphere through their life-cycle. Power-to-liquid fuels e-methanol and e-kerosine are carbon neutral fuels. They are considered carbon neutral if renewable resources are used in the production process and the carbon captured from the atmosphere is later released back into the air.

Zero-carbon fuels are fuels that do not release carbon at the time of usage. For example hydrogen when produced by electrolysis and renewable electricity and ammonia when produced by renewable electricity and green hydrogen as the source are zero-carbon fuels.

Current challenges in replacing fossil fuels with synthetic fuels

To replace fossil fuels by synthetic fuels is a complicated endeavour. There are several options. First, replace a more polluting fuel by a less polluting fuel such as the use of LNG, methanol, ammonia or hydrogen in maritime shipping. To do this, energy density, retrofitting of engines and infrastructure, safety of the fuel, production and price need to be taken into account.

Second, an existing fossil fuel can be replaced by the same fuel with a more sustainable footprint. For example bio-methanol or e-methanol can replace methanol, renewable diesel or bio-diesel can replace conventional diesel, e-hydrogen and solar hydrogen could replace grey or blue hydrogen, solar ethanol could replace ethanol in the future, bio-methane could replace natural gas and bio-LPG conventional LPG. So there are enough options. The choice to switch to the more sustainable fuel depends on the price, availability and emission reduction potential. We give three examples. We start with diesel, bio-diesel and renewable diesel. They can be used in internal combustion engines of vehicles and they have different emission levels as indicated in the biofuels table above. These more sustainable diesels can be blended with petroleum diesel. Switching from petroleum diesel to bio-diesel or renewable diesel becomes attractive if the price gaps between the diesel fuels narrow or move in favour of the more sustainable diesels. Below an overview of the price levels of transport fuels at the end of July in the US. At the end of July bio-diesel (100%) was considerably more expensive than petroleum diesel while renewable diesel was cheaper (other data source though).

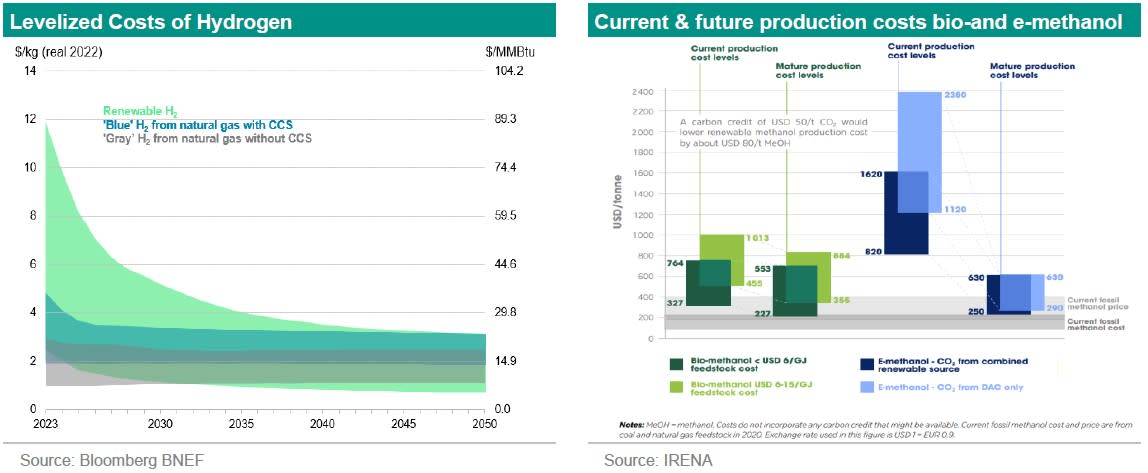

We also have taken a look at hydrogen. Hydrogen could be an important energy carrier for the transportation sector. Among other challenges, green hydrogen is also very expensive compared to blue hydrogen (with carbon capture and storage) or grey hydrogen (without carbon capture and storage). The graph below on the left shows the different levels of levelized costs for green, blue and grey hydrogen. For green hydrogen to become a viable option from cost point of view the costs need to decline substantially.

Methanol is another fuel that could play an important role in decarbonizing the mobility sector with a focus on maritime shipping. Currently methanol trades at USD 313/metric tonne. According to a report from the Methanol Institute and IRENA () the current production cost of e-methanol is estimated to be in the range USD 800-1.600/metric tonne assuming CO2 is sourced from BECCS (Bioenergy with carbon capture and storage) at a cost of USD 10-50/tonne. If CO2 is obtained by DAC (Direct Air Capture), where costs are currently USD 300- 600/tonne, then e-methanol production costs would be in the range USD 1.200-2.400/ metric tonne. Bio-methanol costs USD 700-900/metric tonne. The graph above on the right shows the difference in costs to produce. To make synthetic fuels a viable solution from price point of view, prices have to come down significantly as the examples above show and prices for fossil fuels need to increase which will most likely happen due to ETS 1 and 2.

This article is part of the SustainaWeekly of 23 October 2023