Heating technologies to reduce emissions

Reducing emissions and reaching net zero for heating is a complex task. One option is to burn fuels or mass but these need to be sustainably resourced. Heat can be absorbed from other sources such as the sun, ground, air, water or rest heat. Renewable electricity can also be converted into heat. So there are several options but these options are currently more expensive than just burning fossil fuels.

Reducing emissions and reaching net zero for heating is a complex task

One option is to burn fuels or mass but these need to be sustainably resourced

Heat can be absorbed from other sources such as the sun, ground, air, water or rest heat

Renewable electricity can also be converted into heat

So there are several options but these options are currently more expensive than burning fossil fuels

Introduction:

Life on earth depends on heat for survival. In the classic way, heat is generated by burning something (a fuel or a mass) to heat the air or a liquid that can move in a controlled way. For example, burning wood or gas has been the traditional way of heating. More than 70% of heating and cooling is generated from fossil fuels. To move away from this traditional way of heating and reduce greenhouse gas emissions the process becomes far more complicated. In this note we zoom in on alternative heating technologies to reduce greenhouse gas emissions. We first explain what heat is and then focus on the sources of heat and the technologies.

What is heat?

Heat is the thermal energy that is transferred from one body to another as the result of a difference in temperature. So if two bodies at different temperatures are brought together, energy is transferred, i.e. heat flows from the hotter to the colder body. It is transferred through conduction, convection and radiation. All substances above have , which means that the particles contained in them have some form of . In contrast, when sitting outside on a cold day you will feel "cold" because the heat transferred from the sun to you is less than the radiant heat you are giving off (along with convective heat transfer ). The most significant radiant heat sources in your home include heat from the walls, roof, windows, and your body. Convection is the energy transferred by molecular motion. Radiation is the energy transferred by electromagnetic waves and conduction is the energy transferred by direct contact.

Sources of heat in a zero-emission world

Continue to burn something

To reduce emissions to create heat, fossil fuels could be replaced by fuels that emit less or no emissions. Examples are burning wood from sustainably resourced wood. Burning this wood is carbon-neutral as the CO2 emissions emitted during burning are equal to trapped emissions during the growth of the trees. Another example is the use of bio-gas, bio-methane or bio-LPG but the availability and/or production of these fuels are too limited to replace the use of fossil fuels so this is a major challenge. Burning fuel would be the easiest solution to create heating. Boilers and thermal heat pumps burn fuel to create heat. A boiler heats a fuel to transfer the heat to water. The hot water is then pumped around the home. In power plants, boilers are used in order to produce high pressured steam by heating water so the plant can generate electricity.

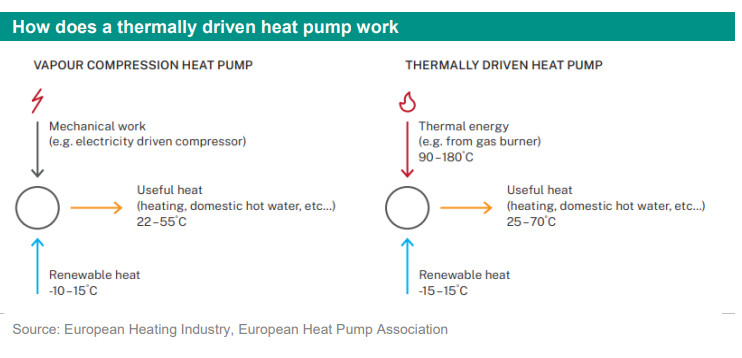

Thermally driven heat pumps are heat pumps using heat or an engine to drive the sorption or compression cycle. There are three types of thermally driven heat pumps: gas sorption heat pump, thermal compression heat pump and gas engine heat pump. The graph above shows how it works.

To absorb the heat from a source

The sun as heat source

It is also possible to absorb heat from a source. It can be absorbed from the sun, from the air or water around us or from the heat deep in the ground. We start with technologies that are able to absorb heat from the sun.

Solar thermal technology converts sunlight into heat, which is then used to produce hot water, heat or even cool buildings. Most solar thermal systems work in combination with a heater. For example, a condensing boiler or a heat pump, which operates when heat demand is too high for the solar system alone. On average, a single family house can satisfy up to 60% of its heat demand for domestic hot water with solar energy. A solar heating system is composed of: solar collectors, roof-mounted elements that collect energy from the sun, a hot water tank to store the water heated by the system, a circuit, and a heat exchanger to transfer heat from the collectors to the hot water storage tank. Installation costs of a solar thermal heating system are generally quite expensive as you have to factor in scaffolding, plumbing, and the required moderations to your roof. An example is solar thermal roof panel. There are two closed circuits with a heat exchanger. In the primary circuit, the cold heat transfer fluid passes through the solar panels. Radiation from the sun heats it and goes to a heat exchanger to transfer thermal energy to the secondary circuit and repeat the cycle. In the secondary circuit, the heat transfer fluid goes to the storage system. Inside the storage system, it gives up its thermal energy to the water stored inside. There are several solar thermal technologies: unglazed solar collectors, transpired solar air collectors, flat-plate solar collectors, evacuated tube solar collectors, thermodynamic solar panels and concentrated solar power.

In unglazed solar collectors a heat conducting material absorbs sunlight and transfers the energy to a fluid passing through or behind the heat-conducting surface. It doesn’t have a glass covering for the absorber. The collectors work best for low-temperature applications (small or moderate) that require a temperature below 30 degrees celsius such as swimming pool heating and space heating.

Transpired solar air collectors typically consist of a dark-coloured, perforated metal cladding material mounted on an existing wall on the south side of a building. A fan pulls outside air through the perforations and into the space behind the metal cladding, where the air heats to as much as 30degreeF-100degreeF (up to 38 degrees Celsius) above the ambient air temperature. The fan then pulls the air into the building, where it is distributed through the building’s ventilation system. The transpired solar collector is a proven but still an emerging solar heating technology. This type of technology is best for heating air and ventilating indoor spaces ().

In glazed flat plate collectors consist of copper tubing and other heat-absorbing materials inside an insulated frame or housing, covered with clear glazing (glass). Glazed flat-plate collectors can operate efficiently at a wider temperature range than unglazed collectors. They can be used for applications of up to about 80 degrees celsius. Flat-plate collectors are often used to complement traditional water boilers, pre-heating water to reduce fuel demand. The design of solar panel is, overall, slightly less compact and less efficient when compared with an evacuated tube system, however this is reflected in a cheaper price. This design of solar can work well in all climates and can have a life expectancy of over 25 years.

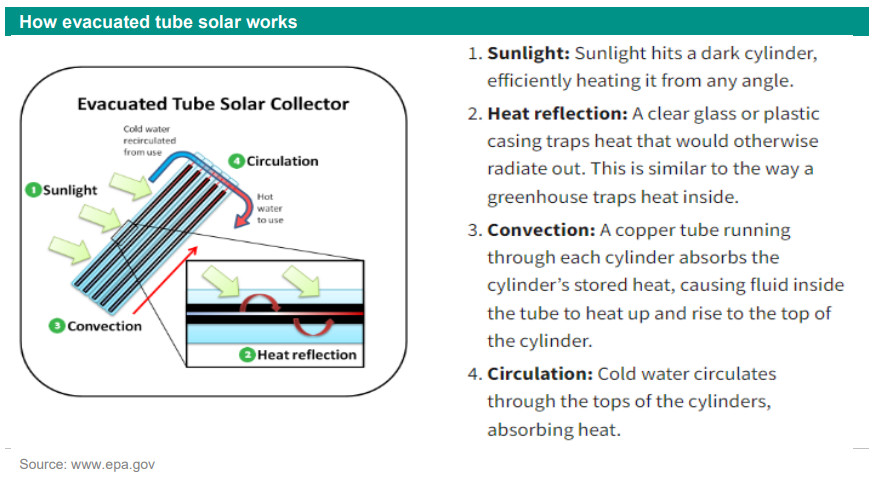

Evacuated tube collectors feature thin, copper tubes filled with a fluid, such as water, housed inside larger vacuum-sealed clear glass or plastic tubes. Evacuated tubes use the sun’s energy more efficiently and can produce higher temperatures than flat-plate collectors for a few reasons (up to 120 degrees Celsius). First, the cylindrical shape of evacuated tubes means that they are able to collect sunlight throughout the day (from many different angles) and at all times in the year. Second, the tubes also have a partial vacuum within the clear glass enclosure, which significantly reduces heat loss to the outside environment - it reduces conduction and convection energy transfer losses. It is one of the most popular solar thermal systems in operation. The tubes can be replaced individually if one becomes faulty, avoiding the need to replace the whole collector. The system is an efficient and durable system with the vacuum inside the collector tubes having been proven to last for over twenty years.

Thermodynamic solar panels are a new development (and need more research and development). They are solar-assisted heat pumps. They are a hybrid between a solar thermal panel and a heat pump. They can create power from not only direct sunlight but also from heat in the air. They may resemble solar panels, but their function is more like a heat pump. They are deployed on the roof or walls and they don’t have to be south facing. These panels work by circulating an extremely cold liquid refrigerant throughout the veins within the panel. As the refrigerant enters the system, it typically has a temperature of around -22degreeC. The panels absorb heat from the surrounding air, transferring the energy to the cold refrigerant. In this process, the refrigerant’s temperature increases, ultimately turning it into a gas. The gas is then compressed which raises its temperature and it will then be passed on to a heat exchanging coil that is located within a hot water cylinder. The hot gas then passes through a heat exchanger, transferring its thermal energy to the water supply, heating it for domestic use. Finally, the refrigerant returns to its original liquid state and re-circulates through the system, starting the process again. The advantage of thermodynamic panels is that they can operate in various weather conditions, even at night or during cloudy days. They absorb heat from direct sunlight, but can also pull heat from ambient air. This is due to their ability to extract heat from the air, similar to how ground source heat pumps work. They can be used for domestic hot water production and underfloor space heating.

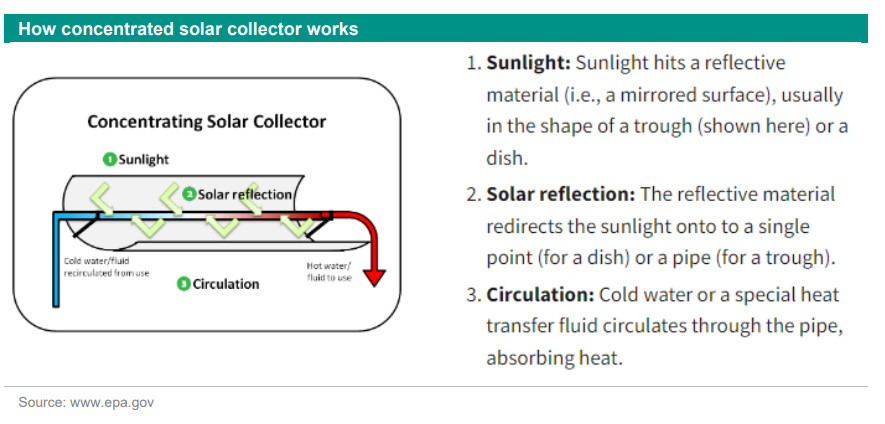

Concentrated solar power (CSP) is an approach to generating electricity through mirrors. This technology uses mirrors to reflect and focus sunlight onto a thermal receiver. The intense CSP energy heats up the fluid (heat-transfer fluid or HFT) in the receiver to high temperatures. This heat or thermal energy is used to turn a turbine and thus generate electricity (source:). The thermal energy contained in the fluid can be stored for later use. CSP energy also has direct industrial applications in water desalination and food processing. Concentrated solar power also has a high energy output, which makes it suitable for large-scale electricity generation. One of the main drawbacks is its high capital and maintenance costs. CSP installations require significant upfront investments, Additionally, the technology is still relatively new, and there’s a lack of experienced professionals in the field.

The ground as a heat source

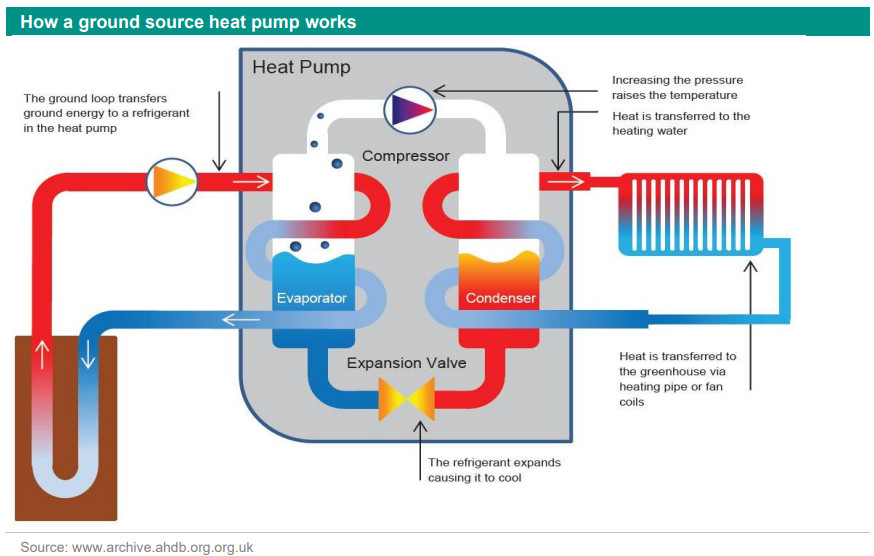

Another source where heat can be absorbed from is the ground. This is done by geothermal or ground-source heat pumps. They can heat or cool and supply even hot water to a home by transferring heat to or from the ground. They can operate in any climate because of the earth’s constant underground temperature. The temperature rises in about 25-30 degrees/km of depth near the surface in most of the world due to the heat flow from the much hotter mantle. The effect of weather, the sun and season only reach a depth of roughly 10-20 m (). Geothermal heat pumps need some electricity to run. They can be connected with solar panels. Heat pumps are very efficient.

Air or water as heat source

The air surrounding us or water close by could by a source of heat. Heat pumps are able to absorb this heat and transfer already existing heat from the environment into a building. They mainly use the energy stored in the groundwater, or air for space heating, domestic hot water, ventilating, and cooling. There are water-water heat pumps and air heat pumps. They are very efficient. They work well with well-insulated buildings; distribution systems working at low temperature, i.e. underfloor heating and large radiators and higher temperature of the heat source (soil, groundwater or air) (source ). But they need some electricity to run.

The heat pump challenge

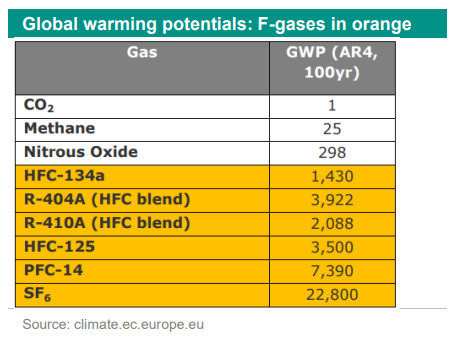

A large number of heat pumps are using fluorinated gases or F-gases as refrigerant. Fluorinated gases are man-made gases that are used in for example heat pumps and switchgear. These F-gases are used sparsely but they are extremely powerful: F-gases are between 1,400-22,800 more potent than CO2. Today, F-gases account for 2.5% of EU greenhouse gas emissions. The heat pump sector has pledged to support the shift from F-gases to natural refrigerants whenever possible and has already achieved significant progress in the monobloc outdoor unit segment. The current EU regulation aims to reduce F-gas emissions by two thirds of the 2014 level by 2030.The European Commission is targeting a reduction of F-gas emissions by 90% until 2050 compared to 2015. On 21 July 2023 EU deal on F-gases was delayed. Three issues created the stalemate: heat pumps, switchgear – the boxes that regulate electrical flow – and Annex IV, which sets out rules for when various kinds of products will be banned. There are already heat pumps on the market with natural refrigerants with lower global warming potential (GWP) such as air, CO2, ammonia, hydrocarbons and water).

Rest heat

Rest heat is the heat released as a by-product of industrial processes or electricity generation. In many cases this heat is wasted. However, using rest heat is becoming more common. It contributes to more efficient energy use, reducing the need for energy sources. There are several ways to use rest heat. Heat recovery refers to the process of reclaiming a portion of the energy wasted by the use of heating, venting and air conditioning systems. Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time. Cogeneration is a more efficient use of fuel or heat, because otherwise-wasted heat from electricity generation is put to some productive use. This involves the concurrent production of electricity or mechanical power and useful thermal energy (heating and/or cooling) from a single source of energy (source: ). Combined heat and power (CHP) it is a highly efficient process (over 80%) that captures and utilises the heat that is a by-product of the electricity generation process. The electricity could be generated from renewables as well. By generating heat and power simultaneously, CHP can reduce carbon emissions by up to 30% compared to the separate means of conventional generation via a boiler and power station. The heat generated during this process is supplied to an appropriately matched heat demand that would otherwise be met by a conventional boiler.

Another way to use rest heat is in district heating. District heating involves generating heat in a centralized location and then distributing it to residences, businesses, and industry in a local area. District heating is the distribution of heat from large scale generation and waste heat sources around large areas, usually within cities, connecting community heating schemes together. Typical central energy sources: power stations, EfW (energy from waste), gas fired combined heat and power units, biomass combined heat and power, industrial heat pumps, solar/geothermal sources. The primary benefits of district heating are threefold: lower energy costs, environmental (through the reduction in carbon emissions) and security of supply.

According to the IEA in 2022 district heat production remained relatively similar to the previous year, meeting around 9% of the global final heating need in buildings and industry. District heating offers great potential for efficient, cost-effective and flexible large-scale integration of low-emission energy sources into the heating energy mix.

Create heat from electricity

The creation of heat from power or converting electrical energy into heat is called in short power-to-heat. Renewable energy sources can produce electricity and this electricity is converted into heat. There are several ways to do that and the applications differ for households and industry. For households the main heaters are electric resistance heaters (baseboard heaters, panel heaters, underfloor heating and wall heaters), infrared heaters or a combination (electric fireplaces). Underfloor heating provide radiant warmth that is transmitted upwards from the floor. Baseboard and panel heaters are convection heaters and electric fireplaces are a combination of infrared radiation and convection.

For industrial applications there are the following forms of heating: resistance heating, induction heating, infrared heating, microwave heating, graphene heating and carbon nanotube heating. We now explain in short, these different industrial heating technologies (source: ee-ip.org).

Resistance heating is a common heating technology that involves passing an electric current through a material with high resistance, such as a metal wire or an alloy. They are controlled with a thermostat. The resistance generates heat, which is used to heat up the material. Resistance heating can be used for temperatures up to 1200degreeC. Induction heating is the technology that involves using electromagnetic induction to heat up a material. It is a non-contact technique for heating metals or other electrically conductive materials by electromagnetic induction. An alternating magnetic field is generated around the material, which induces an electric current in the material, producing heat. Induction heating can be used for temperatures up to 2500degreeC. Infrared heating uses infrared radiation to heat up a material. The infrared radiation is absorbed by the material, which heats up. Infrared heating can be used for temperatures up to 1000degreeC. Microwave radiation is used to heat up a material. Microwaves are non-ionizing radiation. This means they don’t alter atoms and molecules and damage cells like ionizing radiation does. The microwaves penetrate the material and excite the molecules, producing heat. Microwave heating can be used for temperatures up to 3000degreeC. Graphene heating is a relatively new heating technology that involves using graphene to generate heat. When an electric current is passed through graphene, the resistance of the material generates heat. Graphene can be used in electric underfloor heating but also in industrial processes. Graphene heating can be used for temperatures up to 2000degreeC. Carbon nanotube heating is another new heating technology that involves using carbon nanotubes to generate heat. When an electric current is passed through carbon nanotubes, they heat up, generating heat. Carbon nanotube heating can be used for temperatures up to 3000 degree C.

Conclusion

Heating is mostly generated by burning fossil fuels. To reduce emissions and even reach net-zero in 2050 for heating is an enormous challenge. There are several ways to approach this. We can continue to burn something. But then the fuel

or mass needs to be replaced by a more sustainable and low emission fuel or mass. The availability and the production of these fuels are still limited and not enough to replace fossil fuels. There are also other sources to generate heat namely the sun (via thermal solar collectors), the ground, air and water (via heat pumps). The possibilities are available but the costs are still high compared to burning fossil fuel. There is another challenge concerning heat pumps. It is likely that the EU will further strengthen the regulation to reduce the use of fluorinated gases (F-gases) which are used as a refrigerants in heat pumps. This could hamper the roll out and/or acceptance of heat pumps. Rest heat is another source of heat that is mainly been wasted. The potential of rest heat for industry and district heating are substantial. Last but not least renewable electricity could be converted into heat for household and for industry.

This article was part of the SustainaWeekly published on the 18th of September